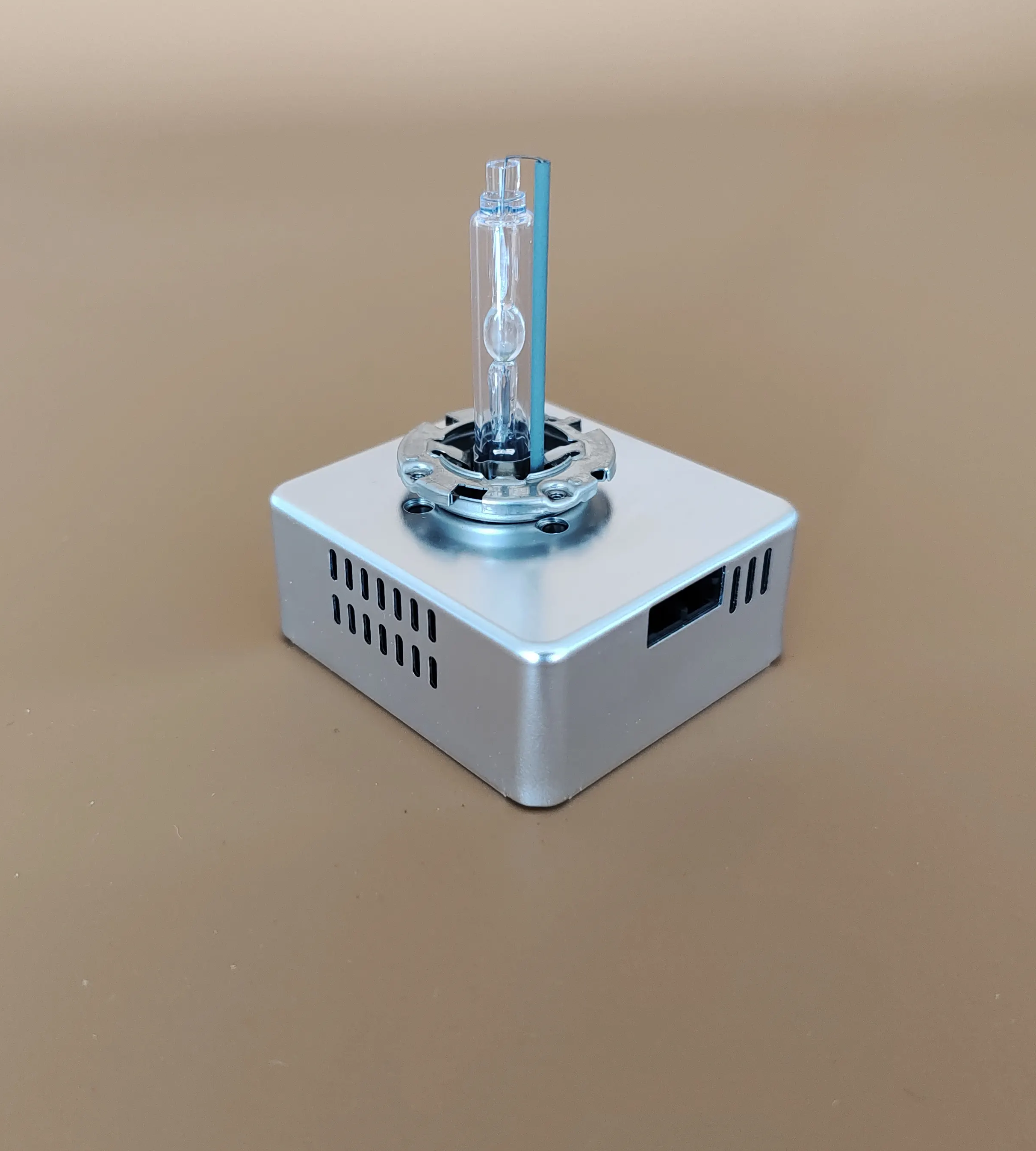

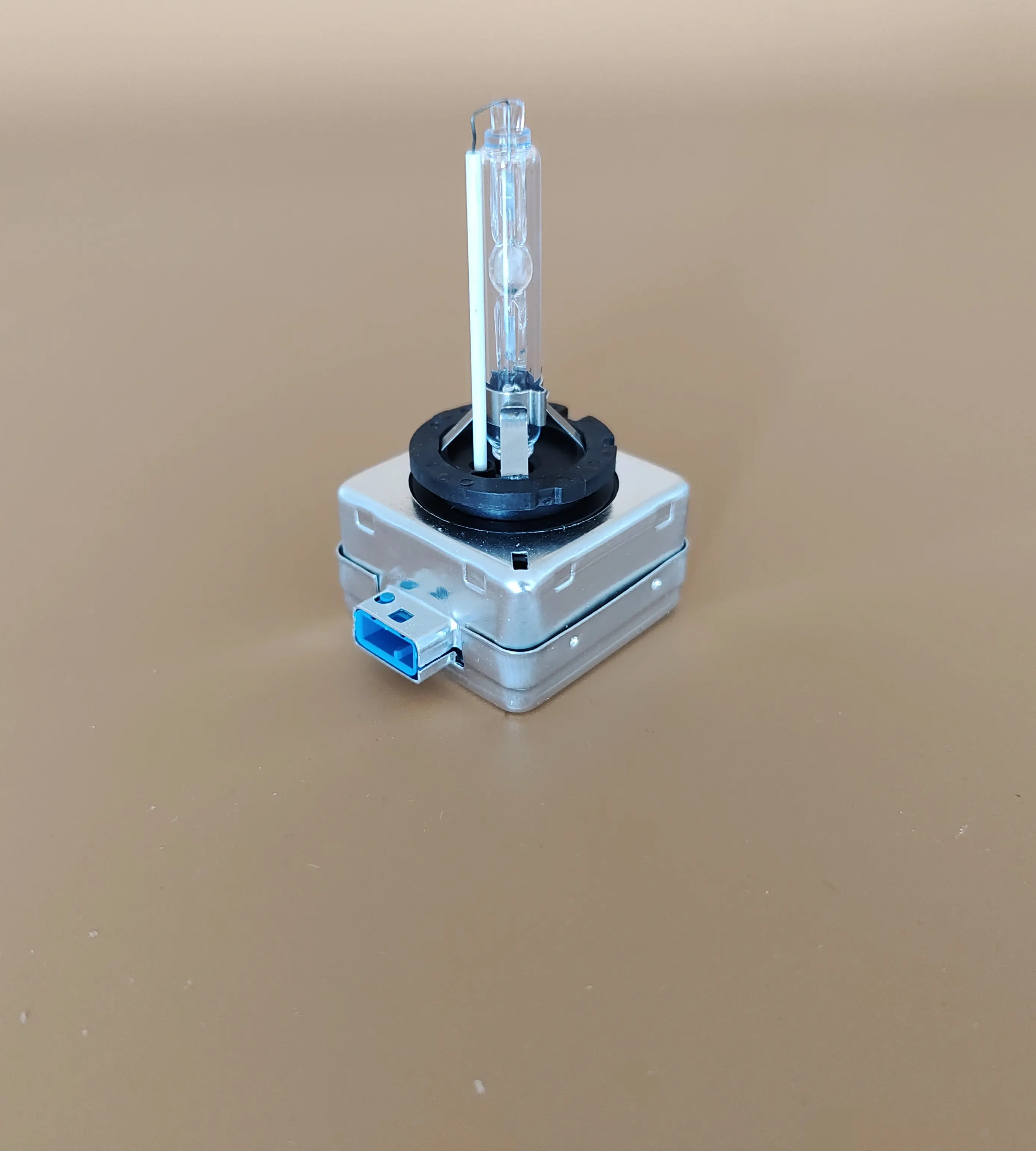

لامپهای زنون NEWBROWN به خاطر روشنایی استثنایی خود شناخته شدهاند و تا سه برابر بیشتر از لامپهای هالوژن سنتی نور تولید میکنند.این شدت نور دید و ایمنی بیشتری را برای رانندگان فراهم میکند، به ویژه در شرایط کمنور.

به بعد جدیدی از دید جادهای با لامپهای زنون با کیفیت بالا از نوبراند دست یابید. این لامپهای زنون به گونهای طراحی شدهاند که نور طبیعی روز را به طور نزدیک تقلید کنند و نوری قوی و روشن ساطع میکنند که به کاهش خستگی چشم در حین رانندگی کمک کرده و زمان واکنش را تسریع میکند. در مقایسه با عمر متوسط لامپهای هالوژنی که به طور قابل توجهی کوتاهتر از اکثر انواع دیگر روشنایی برای وسایل نقلیه است، محصول ما بسیار طولانیتر خواهد بود - که آن را برای هر کسی که فقط به دنبال بهترین روشنایی خودرو برای خودروی خود است، ایدهآل میسازد!

اگر میخواهید خودروی شما طولانیتر عمر کند و بهتر عمل کند، پس برخی از لامپهای زنون NEWBROWN را خریداری کنید. بر خلاف لامپهای معمولی که همیشه سوخته میشوند، این لامپها به گونهای ساخته شدهاند که دوام بیشتری داشته باشند و بنابراین در درازمدت هزینهها را صرفهجویی کنند. همچنین، آنها نوری روشنتر تولید میکنند که هم قابل اعتمادتر و هم ایمنتر برای رانندگی در شب یا در شرایط آب و هوایی بد است - بنابراین واقعاً ارزش سرمایهگذاری در آنها را دارد اگر به ایمنی وسیله نقلیه خود و همچنین ظاهر آن اهمیت میدهید.

دیگر خبری از نور زرد کسلکننده نیست؛ به لامپهای زنون NEWBROWN سلام کنید. این روشناییها نوری قوی و تمیز تولید میکنند که سفیدتر از هر لامپ دیگری در بازار است – این بدان معناست که نه تنها بهتر به نظر میرسند بلکه به شما کمک میکنند در حین رانندگی بهتر ببینید. طیف روشنتر این رنگ سفید به شناسایی رنگها بهطور دقیقتر و قضاوت بهتر در مورد فاصلهها کمک میکند، بنابراین باید سفرهای ما را ایمنتر و لذتبخشتر کند.

ایمنی چیزی است که همیشه باید در اولویت باشد، به ویژه هنگام رانندگی در شب. این لامپ زنون جدید از برند NEWBROWN به گونهای طراحی شده است که نور بیشتری نسبت به هر لامپ دیگری قبل از خود ساطع میکند و بنابراین مناطق بزرگتری را با پرتوهای روشنتر روشن میکند و دیدن واضحتر در نور کم را آسانتر میسازد. دلیل اصلی اینکه مردم باید به تعویض لامپهای قدیمی خود با این لامپ فکر کنند این است که نه تنها دید بهتری را فراهم میکند بلکه همچنین اطمینان میدهد که آنها به همراه دیگرانی که ممکن است از همان جاده استفاده کنند، به طور ایمن سفر میکنند.

شرکت جانچن براون قطعات معدنی خودرو که در سال 2013 تاسیس شد، یک تولید کننده و فروشنده مهم است که در زمینه چراغ های خودرو، قطعات معدنی خودرو، لامپ های هالوجن اتوماتیک و چراغ های جلو اتوماتیک تخصص دارد. کارخانه ما متعهد به تولید محصولات با کیفیت بالا است و این محصولات در بازارهای سراسر جهان از جمله ایالات متحده

تجربه دید برتر با لامپ های هالوجنی خودرو Newbrown. لامپ های ما برای تولید نور روشن و سفید طراحی شده اند که دقیقاً شبیه نور طبیعی روز است، شفافیت را افزایش می دهد و در هنگام رانندگی شبانه، خستگی چشم را کاهش می دهد. با طول عمر طولانی تر در مقایسه با لامپ های استاندارد، لامپ های هالوجنی New

با چراغ های اتومبیل جدید، با اطمینان رانندگی کنید. چراغ های ما برای مقاومت در برابر شرایط سخت آب و هوایی طراحی شده اند، عملکرد ثابت در باران، برف یا مه را تضمین می کنند. تکنولوژی لنز پیشرفته نور را به طور مساوی پراکنده می کند، نقاط تاریک را از بین می برد و دید روشنی از جاده را فراهم می کند. چراغ های جدید ترکیبی

قدم به آینده نورپردازی خودرو با لامپ های LED خودرو newbrown. این لامپ های انرژی کارآمد مصرف انرژی کمتری در حالی که ارائه یک پرتو قوی از نور. طراحی جمع و جور اجازه می دهد تا نصب آسان، و سطح خنک به لمس تضمین ایمنی. لامپ های LED newbrown نه تنها سازگار با محیط زیست بلکه همچنین یک لمس مدرن به

چراغ های زینون قهوه ای جدید، نور بسیار بالایی را تولید می کنند که به طور قابل توجهی دید را به ویژه در شرایط کم نور بهبود می بخشد. تکنولوژی گاز زینون باعث می شود که یک چراغ با نور سفید تر و شدیدتر، دوام بیشتری داشته باشد. لامپ های زینون قهوه ای جدید، انتخاب نهایی راننده هایی هستند که بهترین نور خودرو را

ما مجموعهای از گزینههای سفارشیسازی برای کیتهای بدنه خودروییمان ارائه میدهیم، از جمله انتخاب مواد، تطابق رنگ و تغییرات طراحی. تیم ما بهطور نزدیک با شما همکاری میکند تا اطمینان حاصل کند که محصول نهایی نیازهای منحصر به فرد شما را برآورده میکند.

بله، کتیب های بدن خودروهای ما برای تطابق با طیف گسترده ای از مدل های خودرو طراحی شده اند. ما هر دو کتیب بدن مناسب و مدل خاص را برای پاسخگویی به نیازهای متنوع مشتریانمان ارائه می دهیم.

ما توصیه میکنیم با تیم فروش با تجربه ما مشورت کنید تا بهترین لامپ LED خودرویی را برای وسیله نقلیهتان تعیین کنید. عواملی مانند نوع لامپ، روشنایی و سازگاری با سیستم الکتریکی وسیله نقلیه شما بر انتخاب تأثیر خواهد گذاشت.